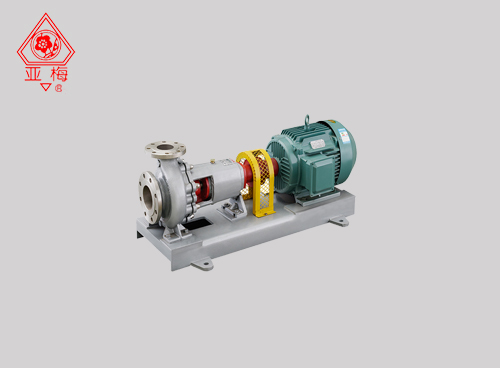

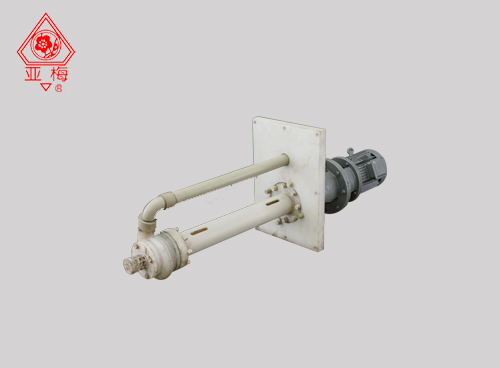

Products

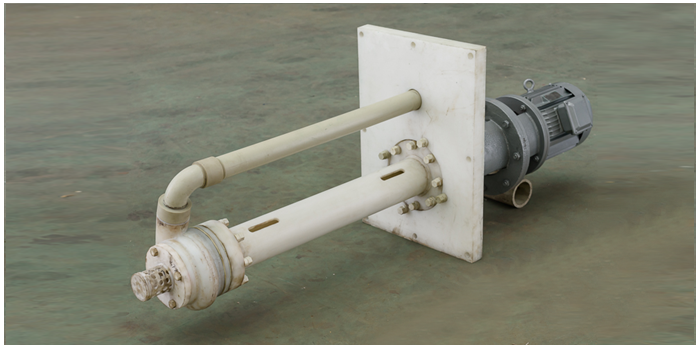

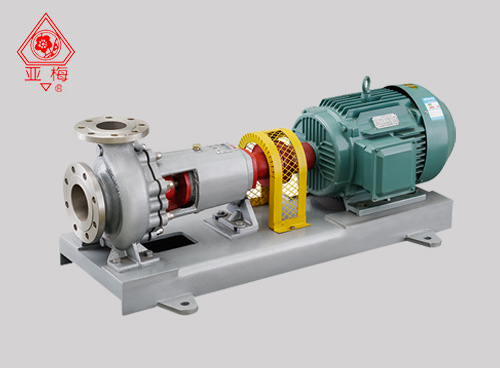

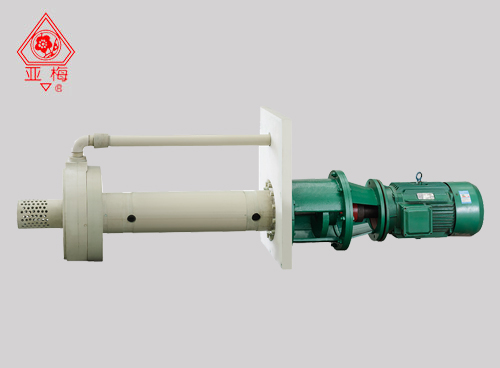

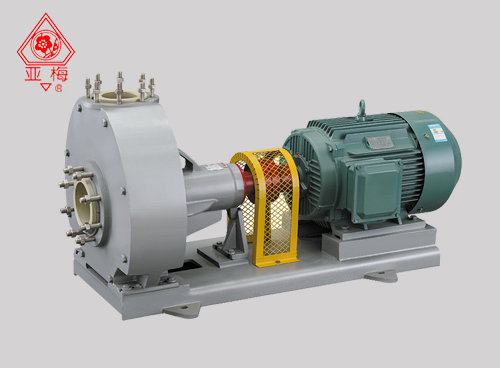

Specialized in the production of "yamei" brand stainless steel corrosion resistance, wear-resisting chemical centrifugal pump and non-metal fluoroplastic pump, the main material is 321, 316, 316L, CD4MCu, 304, 304L, 904, K alloy, T, hastelloy, UHMWPE, F46 and so on.